Products & Services

IBF is able to provide both hot and cold formed welded and seamless fittings ranging from 1⁄2” to 72” NPS in any wall-thickness and any steel grade. The IBF technical department designs products in compliance with all of the applicable Standards/Codes (ASTM, ASME, API, EN, UNI, BS, DIN, NORSOK, GOST, etc.) to satisfy all customers’ technical requirements by means of the best design software. The technical department supports the production design of all heavy tools (e.g. dies) to be used during the manufacturing process.

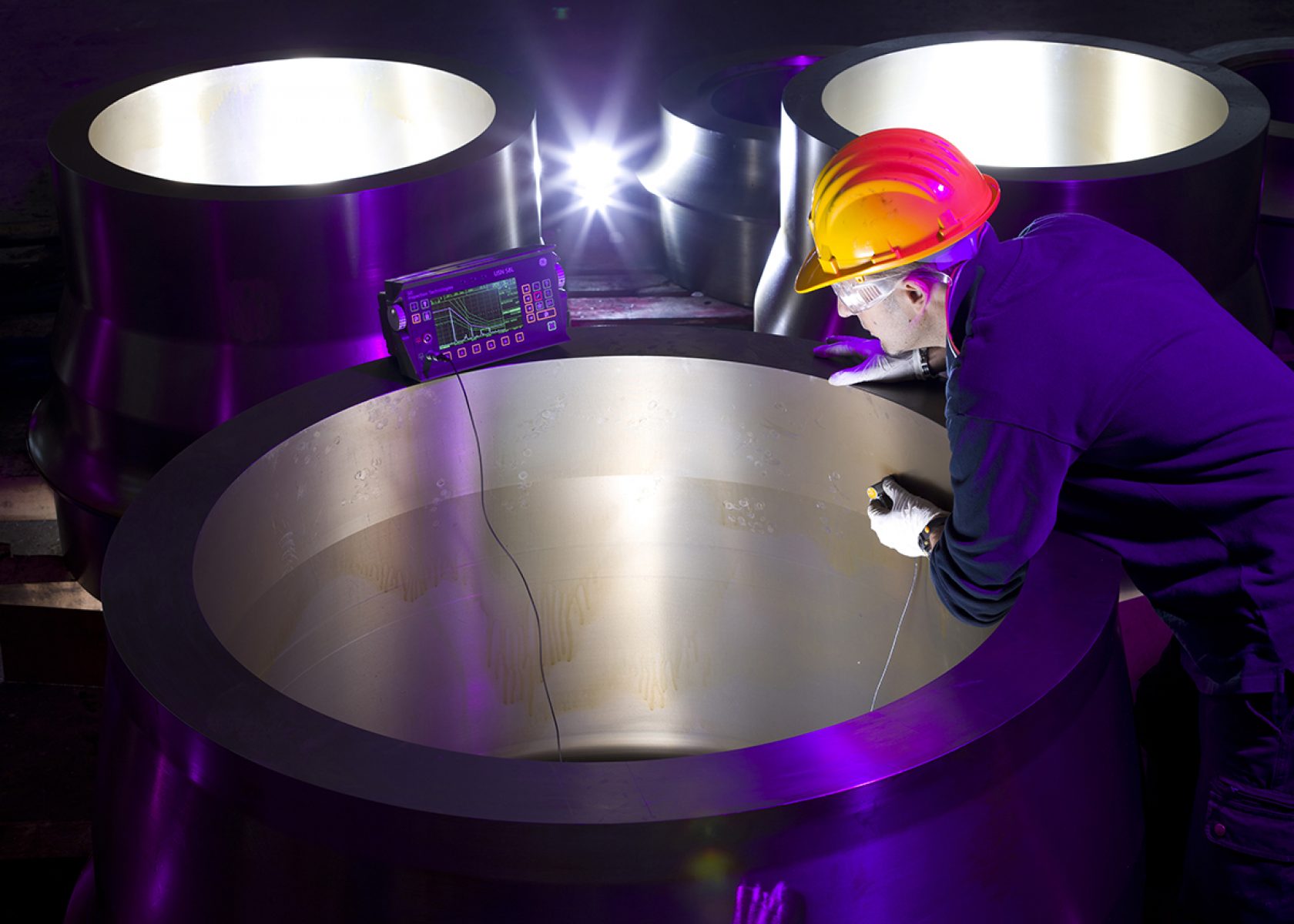

IBF’s products are made by means of very high technology equipped plants. Pipes Division manufactures thin & heavy wall seamless pipes; Fittings Division manufactures a complete dimensional range of fittings welded or seamless. IBF is able to supply tubes and fittings in carbon alloys, ferritic, austenitic and nickel based grades from ¼” – 72”.

The synergy between the two divisions allows the production of special tailor-made parts. Using specially designed equipment and tools IBF can guarantee the highest level of manufacturing feasibility.

Cooperation with the best suppliers, continuous investments in tools and constant research of new processes, allows IBF in looking to the future with the aim of achieving continuous improvement. As a matter of fact, IBF constantly seeks the excellence of its own products through TUBACEX Group own production system, TxPS.

Big OD & ID pipes range

Located in Vittuone (Milan), Italy, IBF Pipes division manu¬factures thin & heavy wall seamless pipes from 6“ to 72”.

| Manufacturing Range | |

| Technology | Outside Diameter |

| Trepaned Heavy wall pipes | From 6” to 72” |

| Cold formed thin wall pipes | from 6” to 24” |

Leveraging on its innovative BOTSP process for the production of “Big OD Thin Wall Seamless Pipes”, IBF pipes can be supplied in cold-worked condition to ensure high strength despite its low weight. IBF’s cold forming technology consists in an advanced CNC controlled machine, developed for the production of seamless tubular components with excellent dimensional tolerances. Long thin walled pipes up to 12m (40’) and 650mm (24”) can be produced with close tolerances and high straightness, starting from short thick-walled preforms. Stainless steel, Duplex, Inconel and other difficult to form materials can be formed using different tooling configuration. IBF uses the most advanced cold forming technology through which it can produce seamless straight with thin wall thickness pipes, with the best tolerances and material properties. Thin walls can be manufactured regardless of the diameters, for the production of large length to diameter ratios. IBF can make long pipes, average longer than 8 meters. As consequence, less welding will be needed during installation with obvious savings and less risks.

| BOTSP-STANDARD SIZES | ||

| Outer Diameter | Wall thickness | Length |

| 150 mm to 650 mm (6″ to 24″) | 3 mm to 30 mm (0.2″ to 1.2″) | 12-14 meters (40′)* |

*Non-standard lengths can also be performed

| Dimensional Tolerances After Cold Working | ||

| Outer Diameter | Wall thickness | Roughness (ID and OD) |

| ±0,8 mm | ±0,2 mm | <1 µm |

| Dimensional Tolerances Heat Treatment | ||

| Outer Diameter | Wall thickness | Roughness after Picking (ID and OD) |

| ±1,2 mm | ±0,3 mm | <2 µm |

*Depending on the Diameter/Thickness ratio

Big OD/ID fittings range

IBF is able to provide both hot and cold formed welded and seamless fittings ranging from 1/2″ to 72″ NPS in any wall-thickness and any steel grade.

IBF has also two subsidiaries specialized in the production of small hot and cold formed fittings: Tubacex Awaji Thailand (TAT) located in Amphur Muang-Samutprakarn (Thailand) and CFF located in Italy as well as a sister company Tubacex Taylor Accesorios (TTA) located in Spain and making small and special fittings such as return bends SR, LR and special radius and other thick wall fittings complementing the Tubacex portfolio.

The IBF technical department designs products in compliance with all of the applicable Standards/Codes (ASTM, ASME, API, EN, UNI, BS, DIN, NORSOK, GOST, etc.) to satisfy all customers’ technical requirements by means of the best design software. The technical department supports the production design of all heavy tools (e.g. dies) to be used during the manufacturing process.

| Manufacturing Range -Fittings and Special Parts | |

| Seamless | Welded |

| 1/2″ ton 44″ (bigger sizes upon request) | 1/2″ ton 72″ |

Special Components

Special components are mainly categorized into the Fittings division and include various products such as: Laterals; Manifolds; Hot Leg, Cold Leg and Surge Line (Reactor Coolant Loop); Stress Joints; Y Tees; Barred tees; flow tees; clad/overlaid special fittings and forgings; 3D/5D piggable bends; Such products are characterized by the use of special alloy materials and require complex drawing capacities and a customized production process due to their uncommon specifications.